Description

The series 65 jet nozzle assembly comprises of a four part assembly, comprising of a weld on socket, tungsten carbide jet nozzle, threaded nozzle retaining jacket and O-ring. This assembly is ideal when building in-hole tools where high presser fluid is used to aid in the cutting (hole opening) by flushing the cutting surface, thus extending the life of the cutters and aiding in the cutting of formations .

Properly placed jet nozzles are proven to increase the rate of penetration (ROP). Increased ROP, reduces time and cost of the hole-opening operation thus reducing the overall operating cost.

High pressure flow, exiting the nozzles adjacent the cutting face, washes cuttings away from the cutting surface thus helping to increase the ROP, while improving the life of the cutters. Efficiently dislodging and moving the cuttings away from the leading edge of the cutter, insurers that cuttings are not being re-cut or act as an abrasives which will shorten the of fixed mechanical cutters.

The Jet Nozzle Assembly socket weldment are offered in two materials, C1045 Alloy Steel and 316 Stainless Steel, but can be special in other materials.

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength while maintaining good weldability.

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. AISI 1045 has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210.

316 Stainless Steel

Our stainless-steel components have proven to improve durability, reducing damage caused by rust and corrosion to the body and nozzle retaining threads significantly reducing maintenance and costly tool repairs”. More importantly nozzle sizes can be quickly changed out in the field, without costly delays and/or down time caused rusted socket/retainer threads, allowing the operator to get back on bottom, focusing on production.

Failsafe Nozzle Tool

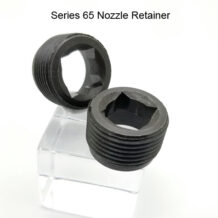

A redesign of the Smith slotted extraction tool has virtually eliminated the problems associated with the design, i.e stripping of the tool and/or retainer slots.

Our retainer design uses a standard 1/2″ (S65) or 3/8″ (S45) socket/breaker bar for removing retainers and nozzles. This improved design eliminating the downtime resulting from damaged tools and/or nozzle slots.

Customer Specified Materials

We stride to meet our customer’s needs. Customers having special design and material criteria are encouraged to contact us for price and minimum order requirements.

Technical Information

For additional technical information on 316 Stainless Steel including information on “Welding Stainless Steel to Mild Steel” please visit our “Technical Specification” page.

Dimension Downloads (PDF)

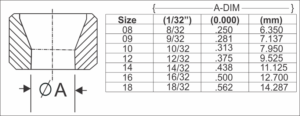

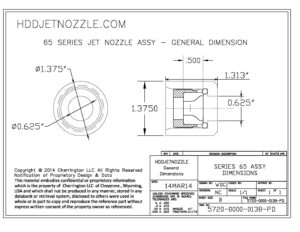

Part No. JNAS65SXX (XX= size 08 | 09 | 10 | 12 | 14 | 16 | 18)

Notice to our users.

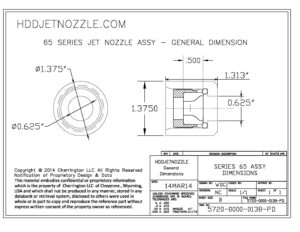

Additional information including (general) dimensions can be found in the attached PDF download links below or on the “Dimension Information (PDF)” for the product i.e. weld socket, retainer, carbide.

HDDJETNOZZLE/CHERRINGTON makes no representation or warranties as to the suitability of said part as it pertains to the end users application.

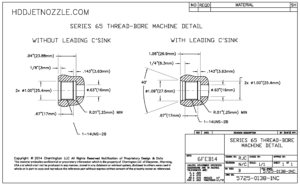

Click Image to Download PDF

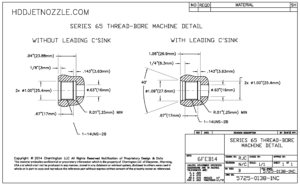

Where drop in sockets cannot be used do to design or space constates i.e. well servicing tool etc., necessitating that the nozzle receptacle be machined directly into the tool body, HDDJETNOZZLE offers users the following “Thread-Bore Machine Detail”.

Thread-Bore Machine Detail

It should be noted the thread-bore details are shown “WITHOUT LEADING COUNTERSINK” & “WITH LEADING COUNTERSINK” leading face. Where space permits, we recommend WITH LEADING COUNTERSINK as it helps protect the lead-in thread and Retainer face.

Alloy/Stainless Physical Characteristics/Welding Notes

AISI 1045 Material/Welding Notes

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength…

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210. (AZO MATERIALS)

Welding AISI 1045 Medium Carbon Steel

AISI 1045 steel is characterized by “good weld-ability”. Best results will be achieved by Pre-heating the sockets before full welding, with optional Stress-releasing after welding.

Certain facts about welding of AISI 1045 steel are:

- AISI 1045 steel is readily welded when correct procedure is followed.

- Welding AISI 1045 steel in through-hardened, tempered and flame or induction hardened condition is not recommended.

- Low hydrogen electrodes are preferred for welding AISI 1045 steel.

- The workpiece is

- Pre-heated at 200°C–300°C (392°F – 572°F)

- Maintained at the same temperature during welding

- Cooled slowly using sand, ashes etc and

- Stress relieved at 550°C – 660°C (1022°F – 1220°F).

Referenced below are links and excerpts from two widely recognized welding authorities for your quick reference. In addition to these, there are many others covering this topic throughout the internet as well as your local welding supply.

When in doubt, consult with a trusted welding distributor for advice on the process. Doing so can help ensure the durability — and the cost-savings — sought in an application featuring both stainless steel and carbon steel.

INTERLLOY PTY LTD – 1045 Medium Tensile Carbon Steel Bar

“1045 is a medium tensile low hardenability carbon steel generally supplied in the black hot rolled or occasionally in the normalised condition, with a typical tensile strength range 570 – 700 Mpa and Brinell hardness range 170 – 210 in either condition.Characterised by fairly good strength and impact properties, plus good machinability and reasonable weldability in the hot rolled or normalised condition.”

DOWNLOAD THIS DATASHEET AS PDF

AZO MATERIALS – AISI 1045 Medium Carbon Steel

“AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of around 60 mm in size being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame- or induction-hardened in the normalized or hot rolled condition to obtain surface hardnesses in the range of Rc 54 – Rc 60 based on factors such as section size, type of set up, quenching medium used etc.”

Download PDF Copy

316 Stainless Material

“Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. It has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. Grade 316 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.” (Written by AZoM)

Grade 316L, the low carbon version of 316 and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). Grade 316H, with its higher carbon content has application at elevated temperatures, as does stabilised grade 316Ti.

Corrosion Resistance

Excellent in a range of atmospheric environments and many corrosive media – generally more resistant than 304. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60 °C. Considered resistant to potable water with up to about 1000 mg/L chlorides at ambient temperatures, reducing to about 500 mg/L at 60 °C.

316 is usually regarded as the standard “marine grade stainless steel”, but it is not resistant to warm sea water. In many marine environments 316 does exhibit surface corrosion, usually visible as brown staining. This is particularly associated with crevices and rough surface finish. (Written by AZoM)

Welding 316 Stainless-Steel

Excellent weldability by all standard fusion methods, both with and without filler metals. AS 1554.6 pre-qualifies welding of 316 with Grade 316 and 316L with Grade 316L rods or electrodes (or their high silicon equivalents). Heavy welded sections in Grade 316 require post-weld annealing for maximum corrosion resistance. This is not required for 316L. Grade 316Ti may also be used as an alternative to 316 for heavy section welding.

316 Stainless Steel Socket welded to carbon steel hole-opener using ER316LSi filler rod.

Referenced below are links and excerpts from two widely recognized welding authorities for your quick reference. In addition to these, there are many others covering this topic throughout the internet as well as your local welding supply.

When in doubt, consult with a trusted welding distributor for advice on the process. Doing so can help ensure the durability — and the cost-savings — sought in an application featuring both stainless steel and carbon steel.

Lincoln Electric

Using 308L, 309L or 316L Filler Metal

“316L (including ER316LSi) filler metal should be used with 316L and 316 base metals. CF-8M and CF-3M are the cast equivalents of 316 and 316L, respectively…”

Hobart Filler Metals

Tips for Successfully Welding Stainless Steel to Carbon Steel

“Welding differing materials, such as stainless steel and carbon steel, can be a more economical choice and it can improve durability of the completed components”.

“When welding stainless steel to carbon steel, it is critical to pay attention to chemistry, mechanical properties and corrosion resistance to avoid potential trouble. For all three factors, choosing the right filler metal can help reduce concerns.

As an example, when joining 304L stainless steel to mild steel, the most commonly recommended filler metal is 309L. During the welding process, the weld becomes diluted with some of the stainless steel from one side of the joint and some of the mild steel from the other side, mixing in material from each side of the weld. The goal is to create a final weld deposit whose chemistry is compatible with each side of the weld joint.”