Description

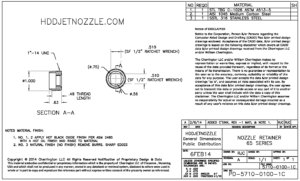

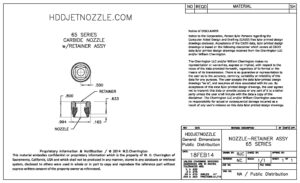

The Series 65 Nozzle Retainer incorporates two unique design features. The retainer encapsulates the carbide nozzle while the threaded design eliminates the failures associated with snap ring retainer designs. The retainers are also designed to accept a standard 1/2 inch drive socket wrench or breaker bar to install or remove the nozzles, a much improved system over the older cross wrench designs.

The nozzles can be used with our serviceable socket weldments or your tooling can be drilled and tapped to accommodate the 1”-14 UNC thread profile.

The nozzle retainers can be ordered in two materials, Steel Alloy (black oxide) as well as 316 Stainless Steel.

Note: Carbide nozzle not included.

Failsafe Nozzle Tool

A redesign of the Smith slotted extraction tool has virtually eliminated the problems associated with the design, i.e stripping of the tool and/or retainer slots.

Our retainer design uses a standard 1/2″ (S65) or 3/8″ (S45) socket/breaker bar for removing retainers and nozzles. This improved design eliminating the downtime resulting from damaged tools and/or nozzle slots.

Dimensional PDF Downloads

Part Number: JNRS65A (Alloy), JNRS65S (Stainless)

Notice to our users.

Additional information including (general) dimensions can be found in the attached PDF download links below. HDDJETNOZZLE/CHERRINGTON makes no representation or warranties as to the suitability of said part as it pertains to the end users application.

Click Image to Download PDF

Retainer Dimensions

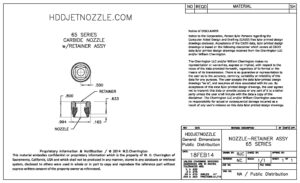

Carbide Nozzle / Retainer Grouping Dimensions

The following drawing provides the overall height dimensions of the NOZZLE/RETAINER ASSY, as may be required by design engineers when designing in-hole tools.

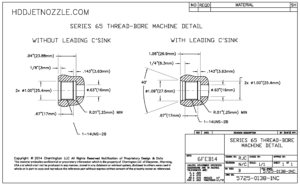

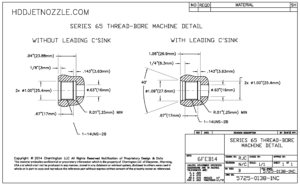

Thread-Bore Machine Detail

Where drop in sockets cannot be used do to design or space constates i.e. well servicing tool etc., necessitating that the nozzle receptacle be machined directly into the tool body, HDDJETNOZZLE offers users the following “Thread-Bore Machine Detail”.

It should be noted the thread-bore details are shown “WITHOUT LEADING COUNTERSINK” & “WITH LEADING COUNTERSINK” leading face. Where space permits, we recommend WITH LEADING COUNTERSINK as it helps protect the lead-in thread and Retainer face.

Material Specifications

Written by AZoM

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of around 60 mm in size being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame- or induction-hardened in the normalized or hot rolled condition to obtain surface hardnesses in the range of Rc 54 – Rc 60 based on factors such as section size, type of set up, quenching medium used etc.

Applications

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

| Gears |

Pins |

Rams |

| Shafts |

Rolls |

Sockets |

| Axles |

Spindles |

Worms |

| Bolts |

Ratchets |

Light gears |

| Studs |

Crankshafts |

Guide rods |

| Connecting rods |

Torsion bars |

Hydraulic clamps |

Chemical Composition

| Element |

Content |

| Carbon, C |

0.420 – 0.50 % |

| Iron, Fe |

98.51 – 98.98 % |

| Manganese, Mn |

0.60 – 0.90 % |

| Phosphorous, P |

≤ 0.040 % |

| Sulfur, S |

≤ 0.050 % |

Physical Properties

| Physical Properties |

Metric |

Imperial |

| Density |

7.87 g/cc |

0.284 lb/in3 |

Mechanical Properties

| Mechanical Properties |

Metric |

Imperial |

| Hardness, Brinell |

163 |

163 |

| Hardness, Knoop (Converted from Brinell hardness) |

184 |

184 |

| Hardness, Rockwell B (Converted from Brinell hardness) |

84 |

84 |

| Hardness, Vickers (Converted from Brinell hardness) |

170 |

170 |

| Tensile Strength, Ultimate |

565 MPa |

81900 psi |

| Tensile Strength, Yield |

310 MPa |

45000 psi |

| Elongation at Break (in 50 mm) |

16.0 % |

16.0 % |

| Reduction of Area |

40.0 % |

40.0 % |

| Modulus of Elasticity (Typical for steel) |

200 GPa |

29000 ksi |

| Bulk Modulus (Typical for steel) |

140 GPa |

20300 ksi |

| Poissons Ratio (Typical For Steel) |

0.290 |

0.290 |

| Shear Modulus (Typical for steel) |

80 GPa |

11600 ksi |