Description

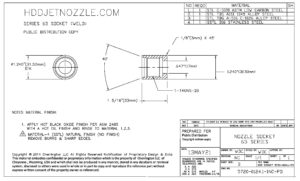

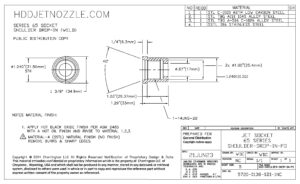

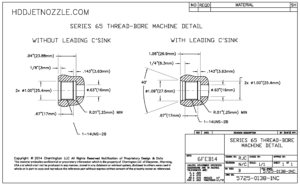

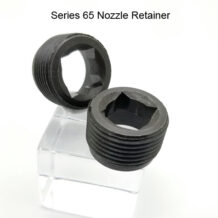

Jet Nozzle Sockets are designed to be incorporated into, and welded to in-hole tools where high presser fluid is used to aid in the cutting (hole opening) by flushing the cutting away from the cut surface, thus extending the life of the cutters or aiding in the cutting of the formation. The sockets can be welded to the surface and/or countersunk into the tooling to provide socket receptacles for the Series 65 carbide jet nozzle and its retainer.

Ideally the positioning of the sockets should be such that high velocity pressure is directed at the interface between the cutting edge of the cutter and the formation, increasing the efficiency of the cutter.

Whereas these parts are offered individually, they are also offered as a complete Jet Nozzle Assembly. These assemblies are an essential part of any drilling contractors, on-site inventory, as they can be quickly incorporated into on-site tooling when unexpected conditions are encountered.

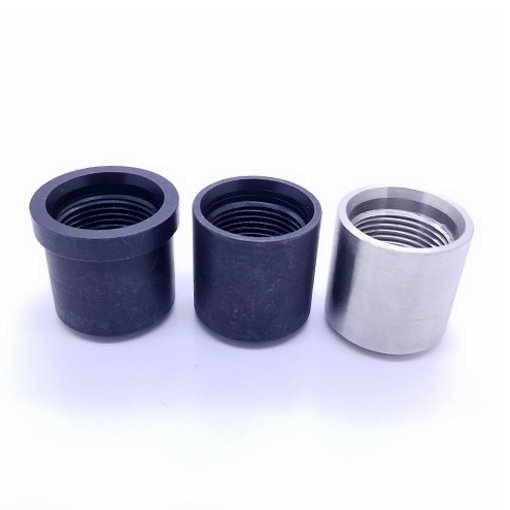

The socket weldment can be ordered in two materials, AISI-1045 Steel Alloy as well as 316 Stainless Steel.

Customer Specified Design/Materials

We stride to meet our customer’s needs. Customers having special design and/or material criteria are encouraged to contact us for price and minimum order requirements.

Material/Welding Data 1045/316

Series 65 Nozzle Socket Materials

- AISI 1045 Carbon Steel Alloy

- 316 Stainless-Steel

Material Weldability

AISI 1045 Carbon Steel Alloy

AISI 1045 steel is characterized by “good weldability and (in-hole) residence to wear”. Best welding results will be achieved by pre-heating the sockets before full welding with optional stress releasing after welding.

AZO Materials

Welding AISI 1045 (AZO Materials)

“Certain facts about welding of AISI 1045 steel are:

AISI 1045 is widely used for all industrial applications requiring more wear resistance and strength.

- AISI 1045 steel is readily welded when correct procedure is followed.

- Welding AISI 1045 steel in through-hardened, tempered and flame or induction hardened condition is not recommended.

- Low hydrogen electrodes are preferred for welding AISI 1045 steel.

The workpiece is:

- Pre-heated at 200°C–300°C (392°F – 572°F)

- Maintained at the same temperature during welding

- Cooled slowly using sand, ashes etc and

- Stress relieved at 550°C – 660°C (1022°F – 1220°F).”

316 Stainless-Steel

Welding Stainless Steel to Mild Steel

316 Stainless Steel Socket welded to carbon steel hole-opener using ER316LSi filler rod.

Referenced below are links and excerpts from two widely recognized welding authorities for your quick reference. In addition to these, there are many others covering this topic throughout the internet as well as your local welding supply.

When in doubt, consult with a trusted welding distributor for advice on the process. Doing so can help ensure the durability — and the cost-savings — sought in an application featuring both stainless steel and carbon steel.

Lincoln Electric

Using 308L, 309L or 316L Filler Metal

“316L (including ER316LSi) filler metal should be used with 316L and 316 base metals. CF-8M and CF-3M are the cast equivalents of 316 and 316L, respectively…”

Hobart Filler Metals

Tips for Successfully Welding Stainless Steel to Carbon Steel

“Welding differing materials, such as stainless steel and carbon steel, can be a more economical choice and it can improve durability of the completed components”.

Material Applications, Physical Properties, Chemical Composition

AISI 1045 Medium Carbon Steel

Written by AZoM

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of around 60 mm in size being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame- or induction-hardened in the normalized or hot rolled condition to obtain surface hardnesses in the range of Rc 54 – Rc 60 based on factors such as section size, type of set up, quenching medium used etc.

For additional information visit AZoM – AISI 1045 Medium Carbon Steel

Stainless Steel – Grade 316 (UNS S31600)

Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. It has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. Grade 316 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

For additional information visit AZoM – Stainless Steel – Grade 316 (UNS S31600)